3D Design Services

3D NYC Lab offers a wide variety of design services for clients of all sizes across any industry. No matter what you are looking to create, we can pair the right software and technology to bring your concept to life through intelligent and thoughtful design. Our process involves close and frequent communication with each and every client we take on to ensure that the final product(s) completely represent the clients concept. Once the client has approved our designs we can export and deliver them in just about any desired format as well as take those designs through a full prototyping and digital fabrication process.

3D Design

For three dimensional design projects, we work with a variety of 3D modeling and CAD software to achieve the best results possible for our clients.

We delivery well-formed, clean 3D meshes that are completely 3D print ready. Once designs have been finalized and approved by the client, we can turn the designs into physical objects through a variety of 3D printing processes. We offer various material type and color options and can find the best fit for each clients project. Learn about a few specific ways to work with 3D design files.

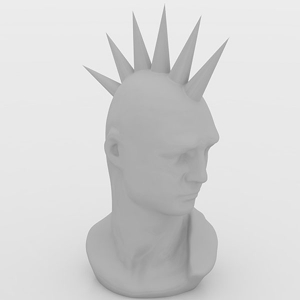

Sculptural

Designs can either be generated with a 3D scanner and then altered to be made 3D print ready, or generated from scratch. Creating sculptural designs in the computer can be effective for a few reasons. As opposed to hand carving out form from blocks of material, many different iterations can be saved and altered. Additionally, a much higher precision of detail can be modeled digitally than by hand.

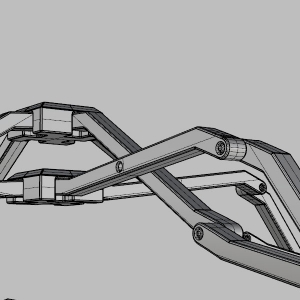

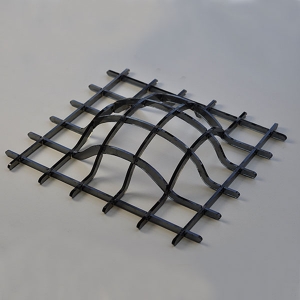

Engineered/Functional

Rapid prototyping has made producing functional parts for testing easier, faster, and less expensive than traditional milling or tooling methods. Using 3D printing as an iterative design tool, we are able to precisely model to test form, fit, feel, and function for a product prototype. Engineered and functional 3D models can include kinetic components and interlocking parts without any assembly required. Because material properties are important to producing functional parts, we can help guide production on the right machine, material, and process for your project.

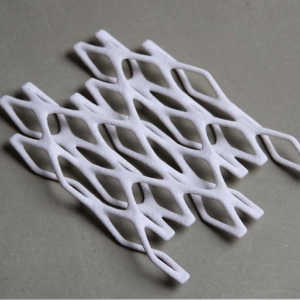

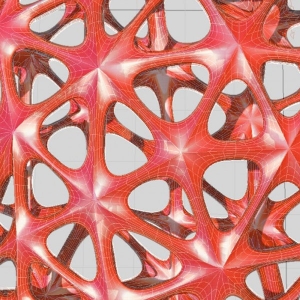

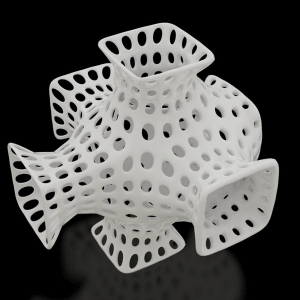

Organic/Complex

Working digitally in 3D allows us to produce designs that are mathematically or algorithmically based which can result in a unique, fluid, formal language of organic complexity. This can include shapes arrayed on a surface, gradients of apertures, physics simulations, rule based surface subdivisions (delaunay/ voronoi patterns) and other forms that could never be designed or manufactured by conventional means. Combining our extensive digital toolbox and access to industry leading fabrication hardware, we can generate stunning, complex 3D models and turn them into a physical reality.

3D Design Examples

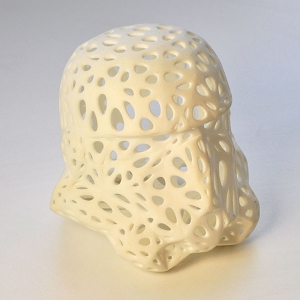

What can you do with 3D design? Well, quite a few things. So many things that it’s almost impossible to count and catalog them all. You can create a model from scratch or build a model using a 3D scanner. Once you have the basic model ready, there are many more things that you can do to tweak and change that model to meet your exact preferences. We took an every day icon that most of you might be familiar with, a storm trooper mask, to walk through a few common customizations applicable to 3D models.

1: Alter an Existing Digital File

Whether the desired outcome is a precise, engineered alteration or some added sculptural detail, we can take a file and then update it. Sometimes an existing design needs an additional feature for a new function, or a 3D file needs color to be mapped onto it.

2: Create a Model with Interlocking Slices

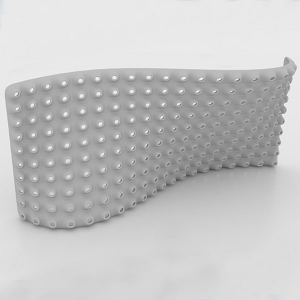

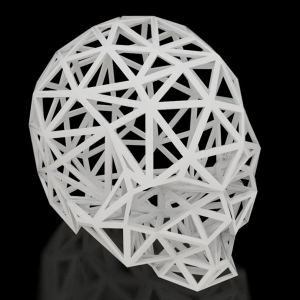

3: Add Complex Surface Conditions, Ornament, or Filigree to a 3D Digital File

Patterns and ornament can be projected or mapped onto a 3D digital file to make very complex objects. This is where 3D printing really shines – and where we can physically realize objects that could never be built by hand.

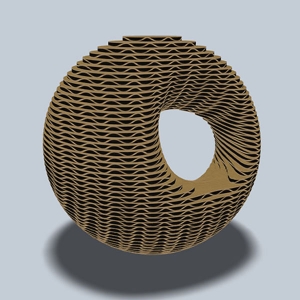

4: Create a Laminated Topographic Model

3D digital models can be sliced into topographic layers which can then be cut from flat sheets of material using laser cutting or CNC milling.

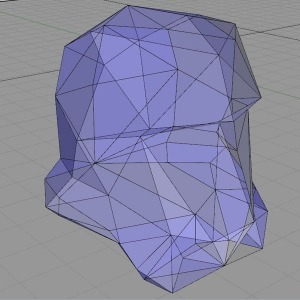

5: Reduce Mesh Resolution of a Digital File

Mesh reduction can be used to achieve a more digital aesthetic, or for preparing files for fabrication in which flat panels of material will be used for construction.